FAQ Frako Capacitors

Frequently Asked Questions FAQ Frako Capacitors

FAQ Frako Capacitors Question 1

Why is the PF capacitor temperature rating important?

When people consider ambient air temperature, they are generally thinking about room air temperature. That’s part of it but not the whole story when it comes to the capacitor inside of an enclosure. Inside the enclosure, the air temperature may be 10°C to 20°C degrees hotter than the room air temperature, due to internal heat generating components such as capacitors, inductors, contactors, fuses, and wires.

FRAKO Type DD60 capacitors have continuous ambient temperature capability of 60°C.

FAQ Frako Capacitors Question 2

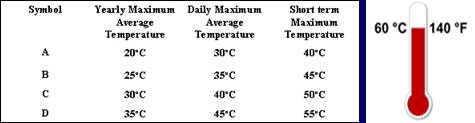

What does a capacitor temperature rating of -40/D or -25/C mean?

The first two digits indicate the minimum ambient air temperature permitted for capacitor operation. The “D” and “C” are indicators of the maximum surrounding air temperature permitted for a capacitor. Many capacitors must be derated when the ambient air surrounding the capacitor exceeds 40°C.

FRAKO Type DD60 capacitors have continuous ambient temperature capability of 60°C.

FAQ Frako Capacitors Question 3

Why do I need a PF capacitor with high current capability?

Capacitors draw two kinds of current: their own (60Hz) current based on its kVAr rating, plus harmonic current. Capacitors are a low impedance path for harmonics and will tend to draw significant harmonic currents whenever there are harmonic producing loads on the same power system. Harmonic currents in capacitors can be excessively high if a harmonic resonance condition exists.

FRAKO Type DD60 capacitors have continuous current capability of 165% of normal capacitor current

FAQ Frako Capacitors Question 4

How can I protect my power factor capacitors from harmonics?

The simplest means of protecting power factor capacitors from the harmful effects of harmonics is to use “detuned PF capacitors”. These capacitors include a series connected reactor that increases the capacitor impedance (ohms) at typical harmonic frequencies. For three phase systems, the best protection is typically achieved with 7% detuning, where the ohms of the reactor equal 7% of the capacitor ohms.

Ask us about detuning reactors.

FAQ Frako Capacitors Question 5

What is the benefit of segmented film?

Due to the dynamic nature of transients, metalized polypropylene film capacitors can be subjected to internal short circuits between layers of metalized film. Self-healing is intended to protect the capacitor, but when the transient is too large to self-extinguish it may penetrate into multiple layers leading to a catastrophic capacitor failure. Self-healing adds life for capacitors… segmented film adds more life for capacitors.

FRAKO Type DD60 capacitors are constructed with self-healing and segmented film that can limit the localized short circuit energy and remove the affected area of the film. The segmented film offers maximum protection against capacitor case ruptures.

FAQ Frako Capacitors Question 6

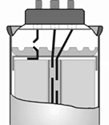

What is the purpose of the internal over-pressure dis-connector?

Each time a capacitor is subjected to a self-healing event, some of the film metallization is vaporized and pressure inside the capacitor increases slightly. The capacitor is automatically disconnected when internal pressure builds to a predetermined level, to minimize the potential for a ruptured capacitor case. Many AC capacitors disconnect only two of the three phases. While stopping the flow of current, this leaves voltage applied to one of the windings.

FRAKO Type DD60 capacitors will disconnect all three phases in case of internal over pressure.

FAQ Frako Capacitors Question 7

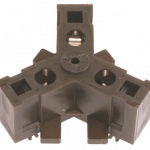

Are there any capacitors with maintenance free terminations?

Most power factor capacitors use some form of screw termination. Screw type terminations tend to loosen over time because they are subjected to heating and cooling due to both capacitor operation as well as ambient temperature variations. As terminals loosen they become a high resistance connection and may produce excessive localized heat resulting in failure of the termination, capacitor or both.

FRAKO Type DD60 capacitors have maintenance free (screwless) terminations that also protect the wires from loosening when subjected to vibration.

FAQ Frako Capacitors Question 8

Why should I use a dry type capacitor?

Most capacitors use either oil or gas to fill the capacitor case after windings are inserted. Oil is useful in capacitors in terms of heat removal and dielectric properties but can leak out, causing a flammability hazard. In other capacitors gas leaks, although undetectable will disable the over-pressure disconnecting device.

FRAKO Type DD60 capacitors are dry type capacitors but have a film of oil applied to the windings where it is most beneficial, and capacitor cases are filled with a dry absorbent granulate.

Contact us with any question you may have. 1-262-618-2403

Call us 1-262-618-2403, Email or visit our Contact us page for Application Engineering or Quotes on Power Factor Control Relays.